|

High-temperature composite

materials on a nickel aluminide base

|

No.

|

Phase composition (mass %)

|

Porosity (%)

|

Content of additives (%)

|

Density (g/cm3)

|

Article shape after SHS densification (m)

|

|

| |

1

|

NiAl

|

2.5

|

0.5

|

5.85

|

f =68, h=18

|

|

| |

2

|

NiAl (claded)

|

> 1

|

1.0

|

5.90

|

f =64, h=10

|

|

| |

3

|

NiAl-3% NbC

|

1.5

|

> 0.3

|

5.93

|

f =64, h=10

|

|

| |

4

|

NiAl-5% NbC

|

> 1.8

|

0.3

|

6.0

|

f =64, h=10

|

|

| |

5

|

NiAl-20% NbC

|

2.8

|

0.6

|

6.2

|

f =68, h=18

|

|

| |

6

|

NiAl-5% Y2O3

|

1.8

|

0.4

|

5.85

|

f =68, h=18

|

|

| |

7

|

NiAl-20% Y2O3

|

5.5

|

> 0.5

|

5.66

|

f =68, h=18

|

|

| |

8

|

NiAl-20% TiN

|

> 7.0

|

> 0.7

|

5.75

|

f =68, h=18

|

|

| |

9

|

NiAl-20% Wfiber

|

1.2

|

0.4

|

8.5

|

40x60x10

|

|

|

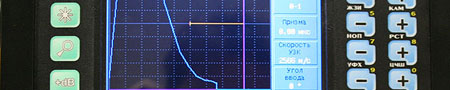

Elasticity of NiAl-based

SHS products as a function of temperature

|

Heat resistance at 1050 and 1150oC

of NiAl-based materials obtained (1, 3) in an arc-vacuum furnace

and (2, 4) by SHS method

|

|